What is a Computer Room Air Conditioning (CRAC)?

A Computer Room Air Conditioning (CRAC) unit is designed for applications where close control, high precision air conditioning is essential. These include data centre cooling, medium and low-density server environments, telecom switching stations, medical operating theatres and clean room environments.

Often, computer room air condition units are considered so critical that they require their own chilled water system. The continuous availability of maximum output means that the whole system cannot benefit from chilled water reset, as a CRAC unit needs water at a pre-defined temperature to ensure peak performance is always available.

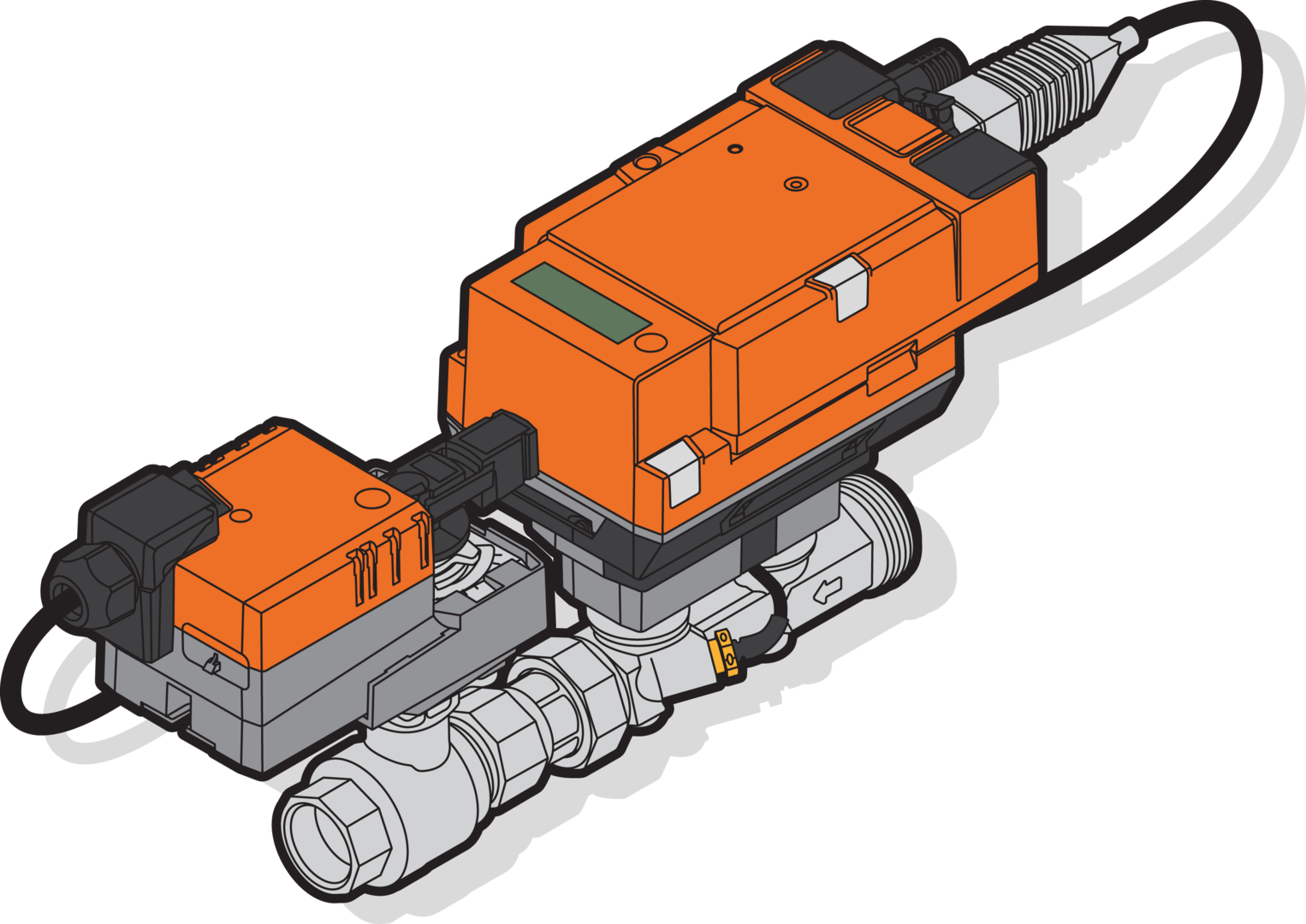

Order the new Belimo Energy Valve™ now

Learn how the Energy Valve improves your computer room air conditioning unit

Common Issues in CRAC Units and Why You Should Choose the Belimo Energy Valve™

Since CRAC units require the ability to address maximum load at any time, the whole system cannot benefit from chilled water reset, as water at pre-defined temperatures is needed to ensure peak performance is always available. Given the critical nature of their task, CRAC units tend to be over selected and over commissioned. The resulting overflow cannot be converted to energy by the CRAC unit, and is reflected in elevated water temperatures or low delta T.

A Belimo Energy Valve™ using power control and delta T management, can ensure that peak performance is available even with varying water temperatures.

Configure your EV to use power control, and set the design power required. The valve will then, depending on the input from the control source, modulate the power output by varying flow, depending on the delta T to achieve the desired output.

Using the formula Q = M x CP x delta T (output = mass x specific heat capacity x temperature difference), you can see that flow and delta T are linked when it comes to heat exchanger performance. We cannot change one variable without affecting the other.

Power control uses this formula to adjust the flow according to power requirements derived from the control signal. Naturally, this is a slow process, so rapid changes in flow temperature do not result in rapid and repeated valve movements.

Application Example

The CRAC unit, shown in the figure below, is required to deliver 29.4 kW [100,000 BTU]. It has a design flow of 1 l/s [16 GPM] and a supply temperature of 7 °C [45 °F], with an expected return temperature of 14 °C [57 °F]. This is considered 'design load' conditions.

Under low system load scenarios, the water temperature supply by the chiller may be increased for promoting energy savings. If the same unit now experiences a supply temperature of 10 °C [50 °F], the higher flow temperature could result in a lower delta T, which would reduce the available output. The Belimo Energy Valve™, having measured a lower delta T, will allow an increase in flow rate to 1.4 l/s [22 GPM] to achieve the required output. In this case, the change in the supply water temperature has no adverse effect on the CRAC unit’s ability to satisfy the required cooling load.

Problem: 100% output requirement prevents variable water flow rates

The figure shows a CRAC unit that is designed to deliver 29.4 kW [100,000 BTU]. Ordinarily, to ensure peak output is always available, it would not be possible to vary the flow temperature.

Solution: Power control-enabled Energy Valve

The figure shows the same unit with the same requirement for 29.4 kW [100,000 BTU]. However, the Energy Valve has detected the increased flow temperature of 10 °C [50 °F], and increased the flow rate to provide the output requested by the control signal.